Sign Up for this FREE webinar

“Make Lean Happen”

|

|

During this 45-minute webinar, you learn:

|

How change process is the fabric of Lean program

How change process is the fabric of Lean program

The strategy, operations and technology cycles of organization and how to adjust

the Lean transformation process according to changing cycles

The strategy, operations and technology cycles of organization and how to adjust

the Lean transformation process according to changing cycles

Human aspects of Lean transformation and what motivates people to embrace Lean

Human aspects of Lean transformation and what motivates people to embrace Lean

Why you need to accelerate Lean transformation

Why you need to accelerate Lean transformation

Definition of Lean transformation, metrics and how they relate to financial measures

Definition of Lean transformation, metrics and how they relate to financial measures

The importance of Lean maturity audits and the right questions to ask to enable

smooth transformation

The importance of Lean maturity audits and the right questions to ask to enable

smooth transformation

How to build a successful Lean transformation plan that addresses both softer and

harder elements of Lean change

How to build a successful Lean transformation plan that addresses both softer and

harder elements of Lean change

How to articulate the business case for change through compelling presentation,

flawless communication plan that delivers the change message

How to articulate the business case for change through compelling presentation,

flawless communication plan that delivers the change message

What Lean transformation implementation issues to anticipate

What Lean transformation implementation issues to anticipate

How to calibrate the speed of Lean implementation when the existing culture and

change are mismatched

How to calibrate the speed of Lean implementation when the existing culture and

change are mismatched

Clearing roadblocks due to resistance

Clearing roadblocks due to resistance

Roles in leading Lean change program – choosing the right sponsor

Roles in leading Lean change program – choosing the right sponsor

How to track success of Lean change

How to track success of Lean change

|

|

|

|

|

Dear Reader,

|

|

Organizational structure changes. Technology changes. Markets change. Markets change.

Tastes change. New competitors arrive. Pyramids get flattened. Work gets outsourced.

Globalization intensifies.

|

|

Notice the word ‘’. It is inevitable and

you need to be prepared for it. Organizations that are aware of the above changes

strive to either survive or grow amidst growing difficulties due to internal and

external factors. For these organizations selecting the right change is relatively

apparent because they cannot afford the huge costs of pursuing and implementing

the wrong change.

|

|

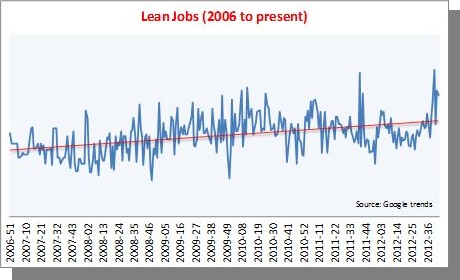

Lean or Lean Six Sigma is replacing all other change initiatives in many organizations

whose leaders believe that moving to Lean organization is the right thing to do.

Let’s look at the ‘Lean jobs’ trends.

|

|

|

The trend is increasing, indicating that more and more organizations have started

bringing Lean trained or experienced people on board to support the change program.

This is evident from the fact that jobs in Lean, including Black Belt positions

grew and achieved breakout since 2006 (that is growth of greater than 5000% in just

6 years).

|

|

The question is ‘Why have Lean as a change initiative?” It is because Lean has power

to deliver results and it is evident from the success of companies that have implemented

Lean. Companies like Toyota, GE, HP and others have been carefully studying the

external and internal drivers before embarking upon the Lean program. They looked

at the competitive pressures as well as customer expectations to build the right

product or service or to design business and manufacturing processes.

|

|

Organizational change has become a way of life as a result of some key forces such

as cost pressures, new competition, and information technology. Organizations are

pressured to introduce cost reduction initiatives, manage complex information flows,

grasp new ideas quickly, and reduce or eliminate the magnitude of any activity that

doesn’t add value to the business. For such organizations Lean is the right tool

to obviate issues related to increased costs, reduced productivity, increased burden

on machines and people, and workload imbalance. Implementing change requires effort,

a huge effort. More than 50 percent of all the effort during Lean program implementation

is spent on dealing with the human dimension of change.

|

|

But what about implications for your organization of such a transformation from

the current-state to a Lean state. How would the people react to such a change?

What infrastructure changes would be required? Will it change the way you perform

your day-to-day work? Lean transformation is no different than any other organizational

change program. Lean transformation is a ‘change’ process. Only

the fittest organizations with the right approach will survive. They understand

how culture impacts change. They know that Lean culture is different from the current

culture and that introducing radical change usually does not gain traction. These

organizations are aware that Enterprise Lean transformation requires modifying the

culture (not radically changing it) to be more in-line with the existing behaviours,

beliefs and assumptions of its current culture.

|

|

So, what is required for an organization to change its culture in favour of Lean?

|

- a clear and compelling case regarding the need for change;

- leadership commitment; employee engagement;

- solutions that are offered with a clear understanding of root causes and preventive

measures;

- ability to weather internal or external ‘distractions’;

- ability and capability to minimize the effect of cycles of strategy, marketing,

organization and technology changes;

- linking the Lean activity to the strategy and a better understanding of the customer;

linking the Lean metrics with financial measures;

- a solid communication plan; and

- training program that covers all of the above, including softer and harder elements

necessary for successful Lean transformation

|

|

Whether you are new to Lean or part of the existing Lean initiative, whether you

are in favour of it or not, the ‘Make Lean Happen’ course will change your perception

and approach toward implementing a Lean program and build confidence in you to accept

it as necessary initiative. It is designed to trigger enthusiasm during the different

stages of Lean implementation. The course will demonstrate how to use Lean tools

in practical situations and how doing so can modify the behaviour of people and

transform the organization gradually to the desired state.

|

|

Finally, the Lean journey is never over. Change is constant. Just as you want to

work continuously to achieve your most ambitious and desired life goals, your organization

leaders will always strive to continuously reduce costs, increase productivity,

and reduce waste to achieve the organization’s goals.

|

|

|